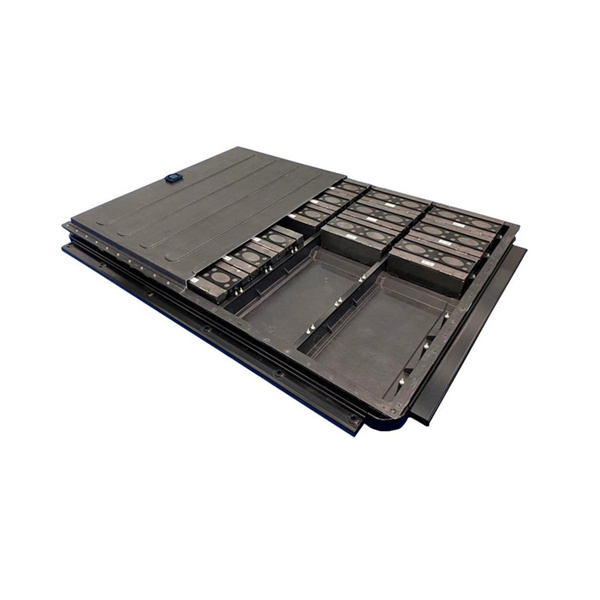

Customized Electric Vehicle Battery Box

At our factory, we specialize in creating Customized Electric Vehicle Battery Boxes. Our products are durable, reliable, and designed for the specific needs of each customer.

Request a QuotePRODUCTS DETAILS

Hot Products

Waterproof Compact Control Electrical Cabinet

Sheet Metal Fabrication Laser Cutting

Industrial Compact Electrical Enclosure Box

Sheet Metal Fabrication Turret Punching

Extra Wide Heavy Duty Sturdy Camp Bed

Stainless Steel Sheet Metal Fabrication Services

comfortable foldable bed with storage

Fabrication Sheet Metal Forming Stamping Parts

Electricity Supply System Distribution Panel

Customized Metal Plate Battery Case

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours